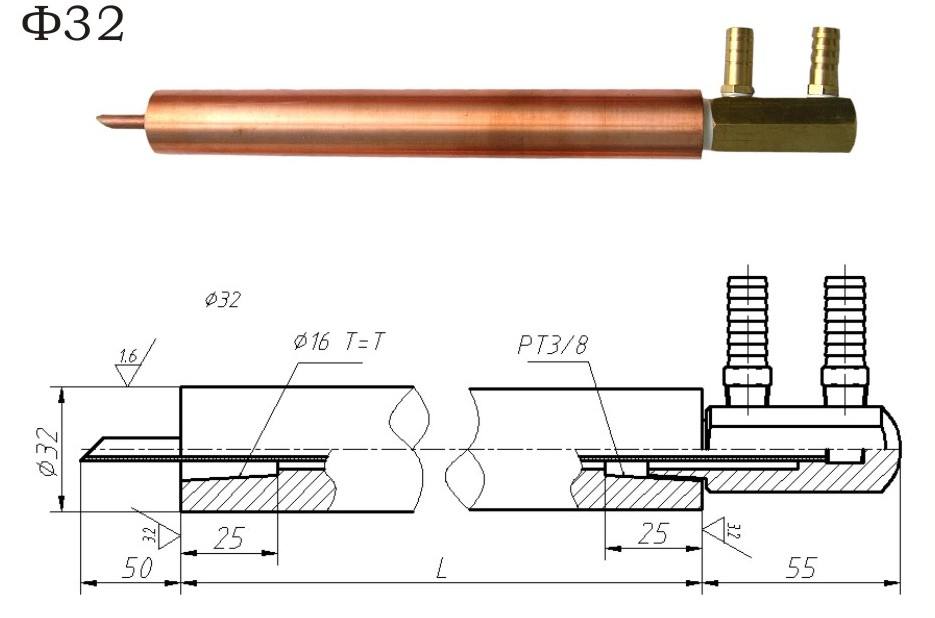

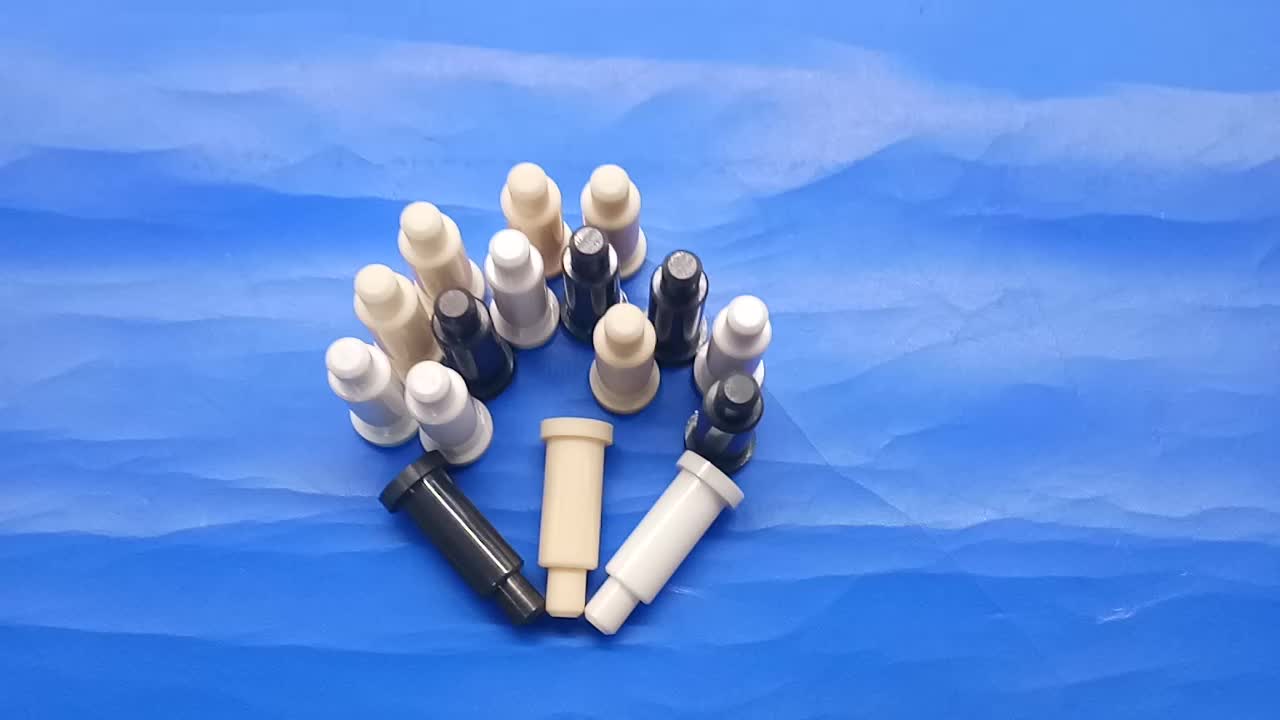

Fewer downtimes due to pin changes and longer maintenance intervals also have a noticeable impact on costs - to say nothing of the unforeseeable costs of complaints due to defective welding. The 40 times longer service life alone demonstrates the potential for cost savings. This reduces the quality of the weld but without any directly verifiable cause. The current no longer only flows through the projection weld nut, but also through the pin. This means that electrical insulation is no longer guaranteed, which results in shunting. However, of far greater concern is a situation where the weld spatter burns the insulation. In the case of projection welding using steel pins and plastic insulation, for example, weld spatter will start to “cling” to the material even after a short period, which can start to influence the manufacturing process. A further advantage is its electrical insulating property.įurthermore, the use of ceramic is recommended for quality and cost reasons. In addition, it prevents the adhesion of weld spatter. Shop M8 M10 M12 M14 Electric Welding Machine Ceramic Positioning pin Ceramic Dowel Electric Welder.

Ceramic dowel pins free#

Ceramic also performs impressively here thanks to its high temperature resistance and consistent hardness as well as flexural strength and impact resistance. Free delivery and returns on all eligible orders. A line downtime of just 10 minutes generates a loss of 25,000 euros.Ĭeramic welding centring pins offer the user a service life that is up to 40 times longer than that of steel pins.

Users enjoy a major benefit in the area of quality assurance because the wear resistance of ceramic positioning pins guarantees consistent tolerances in welded bodywork components for years to come.Ĭeramic positioning pins lead to a significant reduction in costs, especially in automated production. Dowel Pins For Hard To Find Parts: salesunicorpinc.

Ceramic also reaches a multiple of the service life of locating bolts made of steel or hardened steel. The majority of ceramic dowel pins are made from zirconia. These products are available in several different sizes and materials. They are used in a variety of medical and engineering applications. In addition, they are electrically insulating and have a non-stick effect to counter weld spatter. ceramic dowel pins are cylindrical metal rods that are used to align components. Ceramic positioning pins are extremely wear-resistant, even compared with ultra-high-strength, hot-formed steels, such as Usibor.

0 kommentar(er)

0 kommentar(er)